|

TECHNOLOGY SALE or PARTNERSHIP! Economical, Low Capital Process and Equipment for FLOODING TIGHT ROCK. High oil rates from existing multi-fracked wells with no new drilling. Fracture Flooding uses existing fractures as injection and production conduits! 5-US Patents issued: 10,400,562/10,287,863/10,215,005/10,024, 148/9,976,400. 8-Canadian Patents Issued: 2,934,651/2,928,786/2,920,201/2,885, 146/2,855,417/2,835,592/2,820,742/2, 698,454. See the Attached Presentation on Fracture Flooding. Relevant Formations: USA: Bakken, Eagle Ford, Permian, etc. Canada: Bakken, Shaunovan, Viking, Cardium, Montney. New Reformer Technology! Canada Chemical offers a highly efficient Catalytic Partial Oxidation Reformer. We are seeking a PARTNER to assist with Commercialization. Space velocities between 100,000 and 300,000 hr-1 with conversions of 97.9% and CO Selectivity 94.3%, H2/CO Ratio 1.98. |

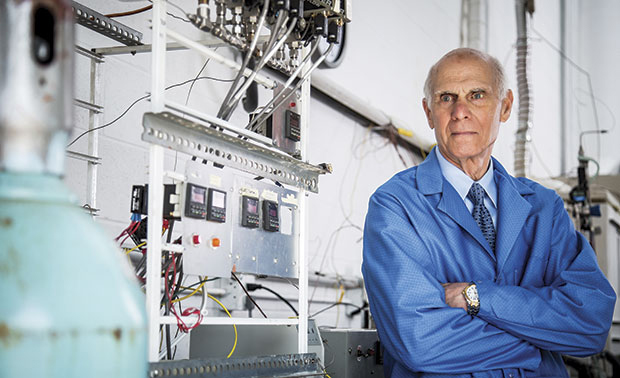

Canada Chemical Corporation

Unit 24, 4807-32 Street S.E. Calgary, Alberta, T2B 2X3 Canada

403.560.7483, Dr. Conrad Ayasse  We are an Innovation Company: We Break New Ground CONRAD AYASSE PATENTS, February 6, 2015

CPTL is 57% owned by Canada Chemical Corporation.

|